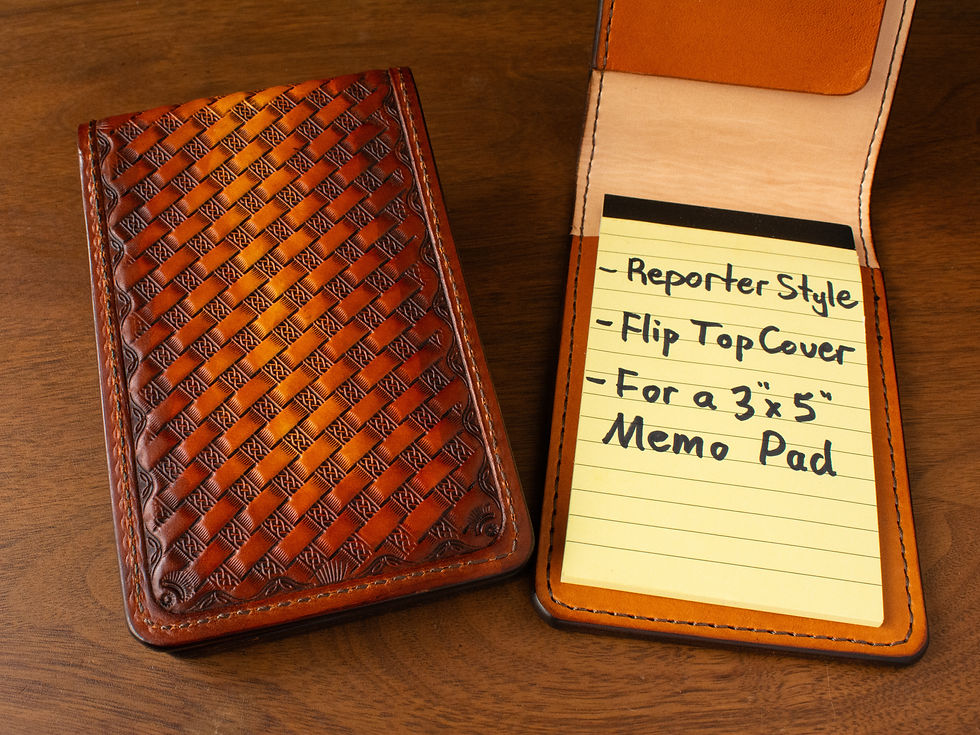

Connor Rademaker

Artist & Craftsman

Hand crafting elegant, durable, leather goods for the modern professional since 2010.

Keeping alive the proud American tradition of leathercraft with modern takes on classic designs and motifs.

Click the "Visit Shop Button" to see my current inventory, or continue scrolling

to learn more about the process that makes these pieces truly special.

The Process

Hand-made for unrivaled beauty and durability.

Always Cut by Hand

Mass manufactured leather goods are cut, not with a knife, but with a hydraulic press and die.

While I cannot compete with the speed of this cookie-cutter approach, it is inflexible.

Working by hand allows me to make small adjustments to my designs over time, continuously iterating and refining as each piece and each customer teaches me something new about the craft.

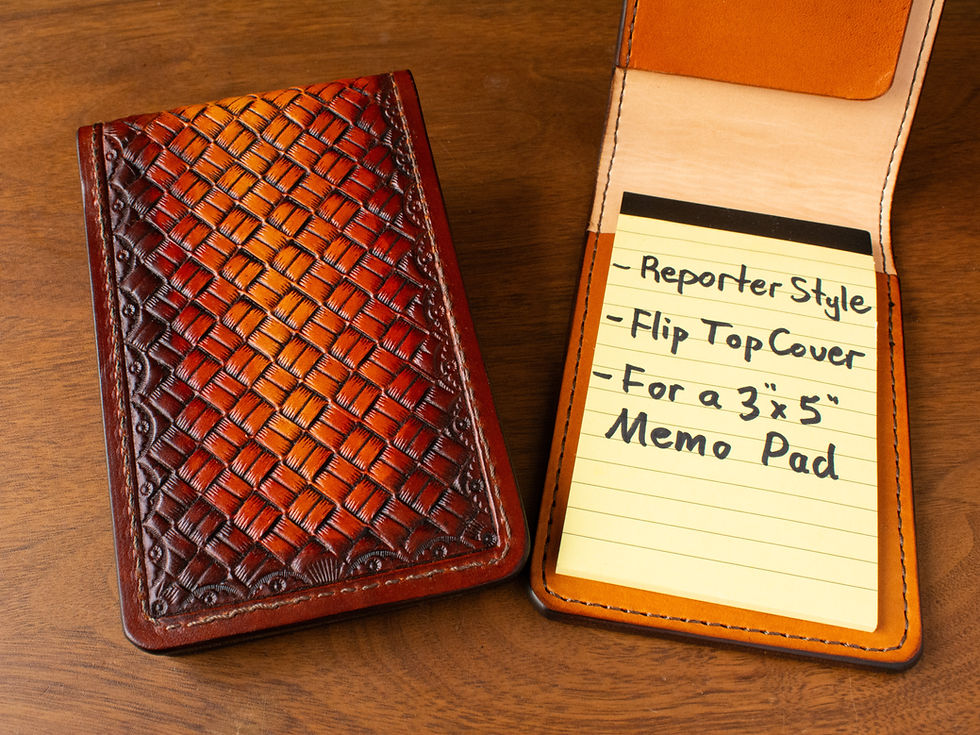

Dyes & Finish

With long drying times between each step, each piece of leather goes through a days long process between the raw and finished material.

Oils are added to provide flexibility and longevity, several coats of dye create deep, rich colors, and a thin clear finish adds beautiful luster and protects the material below.

Assembly & Stitching

I offer both hand stitched and machine stitched versions of most of my goods.

Hand stitching provides an unparalleled degree of durability, beauty, and refinement.

Machine stitching make these goods much more accessible to a wider audience.

All metal hardware is always solid brass or solid stainless steel, with no cheap plated finishes to wear away over the first year.

Polished Edges

The final touch, and one often skipped by lesser craftsmen looking to save a little time where it might go unnoticed.

When freshly cut, the edges of each piece of leather are square and rough.

Each edge is sanded to be round, flush and smooth, then carefully brush dyed, and when fully prepared, polished to a glossy finish.